Eight new aluminum materials to be developed by MIIT (3): high performance automobile

All semi-finished aluminum products (plate, strip, foil, tube, bar, mold, wire, powder, forging) are widely used in automobile manufacturing. In addition to these pressure processing materials, aluminum alloy die castings and castings are indispensable metal materials for automobile manufacturing. In 2018, the world will produce about 52 million cars and consume 114 million tons of materials, of which metal materials account for about 82%, of which 93.4 million tons are used, of which aluminum and aluminum alloy only account for 6.5%, the rest are steel and cast iron, and the consumption of other non-ferrous metals is very small.

Application of 6xxx series aluminum alloy plate in automobile manufacturing

Almost all aluminum materials have been widely used in automobile manufacturing, but most of them are cast aluminum alloy, which is used to produce die castings and castings. No automobile does not use aluminum and aluminum alloy castings. The amount of casting aluminum alloy accounts for 65% of the total amount of automotive aluminum, and the total consumption of semi-finished aluminum is less than 35%. More than 70% of the total amount of aluminum used is plate, while the most used plate in China is thin plate with thickness ≤ 2mm, accounting for more than 92%.

The high-performance aluminum alloy sheets for automobiles proposed by the Ministry of industry and information technology are: 6016-s, 6016-ih, 6016-ibr, 6a16-s, 6a16-ibr, 5182-rss, 5754, 6022, etc. the elongation of typical 6xxx series aluminum alloy sheets is A50 ≥ 25%, R value is ≥ 0.60, yield strength Rp0.2 after 60 days parking is ≤ 140n / mm2, and yield strength increment of baking paint hardening is ≥ 80N / mm2.

The aluminum alloy plates used in automobiles can be divided into two categories: high performance sheet for covering parts such as passenger car, pickup truck and minibus, namely ABS. Most of the plates used in other automobiles, such as buses and tank cars, are commonly used in industry.

Application of 6xxx series aluminum alloy sheet in automobile

In 2018, China produced 27.8092 million vehicles and sold 28.806 million vehicles, including 23.5294 million passenger cars and 23.7098 million commercial vehicles, and 4.2798 million commercial vehicles.

In 2018, about 8.6 million passenger cars in Europe and the United States used aluminum alloy plates in manufacturing, nearly 38% of passenger cars in North America used aluminum alloy engine covers, and nearly 1.5 million passenger cars in Japan used aluminum alloy plates. In Europe and North America, 6xxx alloy sheet is widely used, 6016 alloy is used in Europe, and 6111 alloy is preferred in America. The main consumer countries are the United States, Germany, Japan, South Korea, Canada, Switzerland, the United Kingdom, Italy, etc. among the 1.05 million tons of ABS consumed in 2018, the United States accounts for about 19.5%, Germany accounts for about 13%, and Japan and Switzerland account for 7% respectively.

The BMW 7 series passenger car made by BMW in Germany has also made amazing achievements in weight reduction. Its skeleton is composed of carbon fiber reinforced composite (CFRP), aluminum alloy extrusion material and high strength steel. Due to the ingenious combination of these three materials, the comprehensive performance of the car is greatly improved, the net weight of the car is significantly reduced and the fuel efficiency is improved.

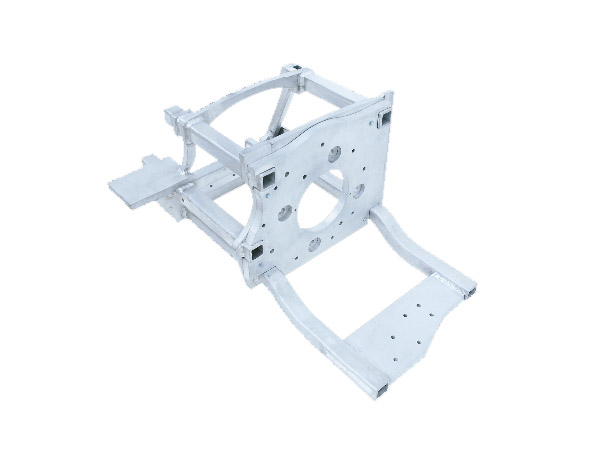

6xxx aluminum alloy sheet metal parts for automobile

6xxx series alloy is the most widely used aluminum alloy in automotive industry. It has excellent formability, high strength, corrosion resistance, folding edge and high surface performance. At the same time, the strength of 6xxx series alloy is improved after baking.

Using aluminum alloy plate instead of steel plate can reduce the body weight by 40% ~ 50% and reduce the net weight of the vehicle by about 10%. Ford Model T, Ford prodigy, fordt-150 pickup, Jaguar XJ, Ferrari 360, Chrysler prowler, Volkswagen 31lupo, Audi A2, A8, the Honda Insight, Honda NSX, test model, s are all made of aluminum. The use of ABS to manufacture the engine cover and trunk cover is countless.

Properties of typical plate alloys

6016 alloy is widely used in ABS, but the heat treatment process is complex. In order to obtain good properties, T4P must be pre aged between solution treatment and baking treatment. Because of the good formability before stamping, and in the process of baking paint after stamping, the strength can be improved rapidly, so it has high dent resistance. 6016 alloy plate after solution-t4p-paint treatment can take into account these two requirements, but the process parameters have a great impact on the final performance. Insufficient solution treatment reduces the precipitation power of T4P and the artificial aging in the process of baking. Long holding time may lead to grain coarsening, and low pre time effect humidity will reduce the stability of the plate during the placing process and the hardening effect during the baking process, Too high temperature will affect the formability of stamping process. Therefore, it is necessary to optimize the process parameters of solid solution and T4P to obtain ideal comprehensive properties.

The precipitation process of 6016 alloy Al Mg Si alloy during aging process is: α (AL) solid solution → β "→ β". The strength of the plate is mainly affected by solution strengthening, pre aging and natural aging strengthening. During solution treatment, the soluble phase dissolves into α (AL) matrix, resulting in solution strengthening. In the subsequent T4P process, the supersaturated solute atoms will form aging precipitates The size, quantity and morphology of the alloy are closely related to the pre aging temperature. On the one hand, aging reduces the supersaturation of matrix and weakens the effect of solution strengthening. On the other hand, pre aging precipitates can enhance the strength of the plate; the strengthening effect of natural aging increases monotonously with time, and tends to be stable after reaching a certain time.

The research results of Zhang Zedong and other experts show that the solution treatment at 560 ℃ / 1min of 6016 alloy plate can obtain good effect, and extending the holding time is not good for the performance; considering the performance requirements of 6016 automobile plate, the industrial production can be achieved