Application of extruded aluminum profiles in various parts of electric vehicles

wheel

There are four aluminum alloy wheels for electric vehicles. The wheels of household and public vehicles are low-pressure casting. Zlxxx series aluminum alloy casting is widely used. China is a big producer of cast aluminum alloy wheels, accounting for more than 60% of the world's total output. Wheels are important security parts and have high safety requirements. Aluminum wheels have the advantages of light weight, good heat dissipation, high dimensional accuracy, and high dimensional accuracy The aluminum wheels of large buses, sports cars, luxury cars and some special vehicles are forged with 6 series alloy.

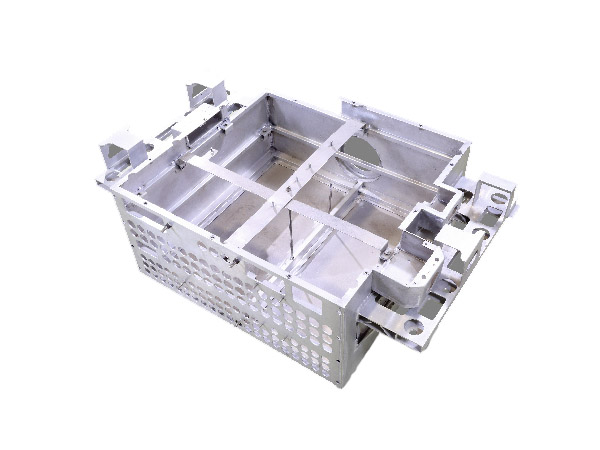

Battery system

The battery system mentioned in this paper does not include the battery itself, which refers to the battery pack, battery pack frame and water cooling plate. The three major parts manufactured by Liaoning Zhongwang Group Co., Ltd. are all made of extruded aluminum. The weight of steel battery pack frame is 110kg ~ 140kg, while that of aluminum alloy frame is only 40kg ~ 50kg. Battery pack parts are composed of frame beam, longitudinal beam, bracket, positioning pin, etc New energy auto parts Co., Ltd. is a leader in the production of battery box tray.

Panel

All the passenger car covers are basically the same, including front and rear cover plates, roof plates, left and right plates and other sheet metal components. All aluminum plates are basically the same. Commonly known as auto body sheet (ABS), they are all rolled with 6 series alloy. However, it should be pointed out that at present, both ABS and other aluminum plates for civil products are developing towards low-carbon or green direction, in other words, alloy The more the content of old waste, the less carbon content of material. Nobilis aluminum and hydro aluminum are the leaders in this field. The old waste content of advanztm alloy sheet produced by nobilis Aluminum Co., Ltd. has exceeded 85%. In 2018, more than 180 automobile manufacturers in the world have used this series of alloy plates to manufacture automobile sheet metal parts, which not only achieves good results in automobile lightweight, but also reduces material costs while improving automobile performance.

Nordic hydro Aluminum Co., Ltd. has successfully developed circal75r and reduxa alloy series. Their scrap aluminum content is more than 75%, and the maximum carbon footprint is 4.0KG CO2 / kg aluminum.

Profile skeleton

The body frame of the all aluminum car is made of all aluminum and is made of extruded aluminum profiles. At present, the connection of the framework is mostly by welding or bonding process, which is not special for electric vehicles.

The Internet of things plays a key role in how to drive people to the destination and communicate with the outside world. The Internet of things plays a key role in identifying the upgraded signposts, signs, camera networks, pedestrians and other vehicles, and the sensors that communicate with them will synchronize the movement of vehicles, thereby minimizing power consumption and improving traffic conditions, and helping the management to control. Subgrade, because wheel sensors will tell them the road condition. The thermal sensor on the electric vehicle will let th