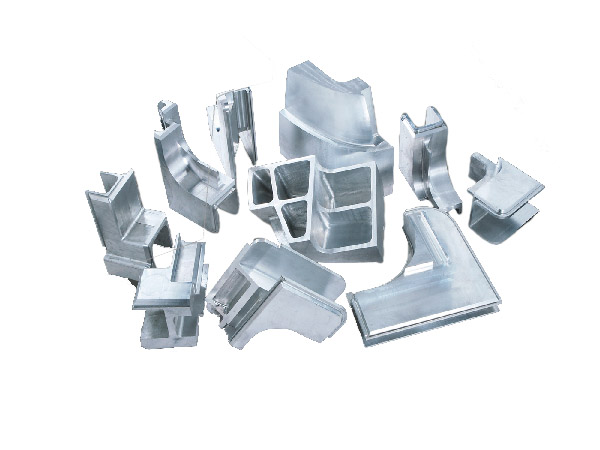

How to ensure the accuracy of industrial aluminum profile cutting

The deep processing process of industrial aluminum profile includes cutting, drilling, tapping, milling groove, installation and so on. As the main processing procedure, cutting plays an important role. A profile has a length of 6 meters, which can be assembled and used after cutting. The aluminum profile cutting is carried out according to the processing drawings. The accuracy of the cutting should be guaranteed so as not to affect the later use. So how to ensure the accuracy of industrial aluminum profile cutting? Shanghai Jinlv will explain it to you.

Industrial aluminum profile cutting

1. Choose a professional saw blade, because the hardness of industrial aluminum profile is not as big as steel, so it is relatively easy to saw. However, due to the hardness is not large enough, it is easy to stick aluminum. Therefore, the blade must be sharp and must be replaced after using for a period of time.

2. If you choose the right lubricant, if you do not use lubricating oil to cut directly, there will be a lot of burr on the cutting surface of aluminum profile, which is difficult to clean. And it hurt the saw blade.

3. Cutting to use a professional CNC cutting machine, so that the length of the cutting error will be small. Generally, the error of length cutting is within ± 0.5mm, and the error of angle cutting is within ± 1 degree.

4. The professionalism of personnel. The accuracy of cutting is not only affected by mechanical equipment, but also by the proficiency of personnel. An experienced cutting personnel, will be in strict accordance with the drawings for processing, to ensure the accuracy of cutting requirements.